"Perfect forming solutions"

DESIGN | Development | production | LOGISTICS

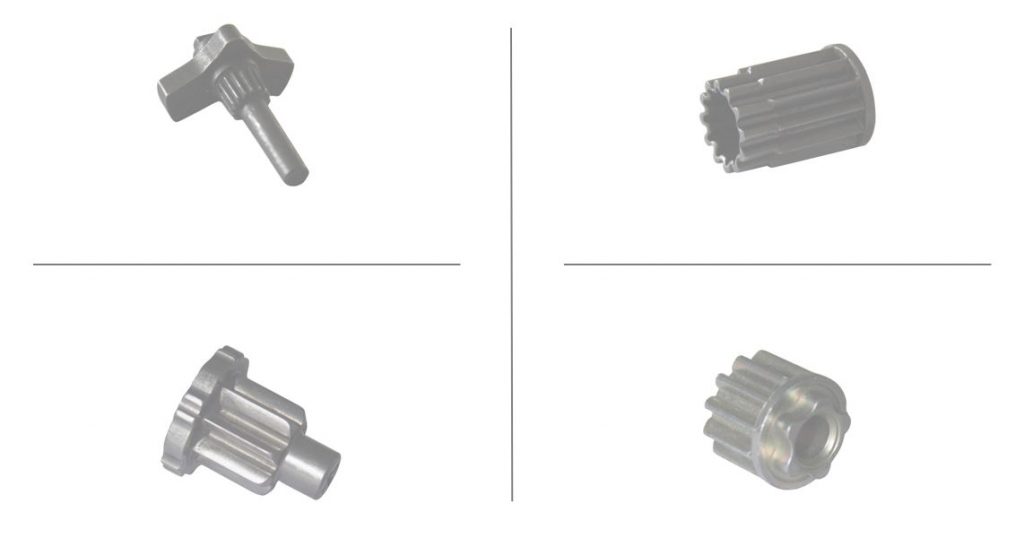

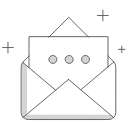

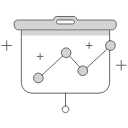

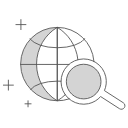

COLD FORGING

Production of complex, precision parts with high accuracy, economically and in large quantities with high repetitive tolerances.

Advantages of Cold forging

Material cost saving

The cold forming process enables material cost savings up to 60% (depending on product shape) by significant reducing of the production of scrap.

Production throughput time

The high speed of this manufacturing process reduce the production costs. Speeds range from 50 ppm til 200 ppm.

Reliable production process

Cold forming is a very stabel and consistent production process which not only allows to produce reproducible parts, but also helps to keep the costs in line due to high productivity and efficiency.

Grain structure of material

Products possess excellent strength, as the material flows into its final form, rather than being cut, as in machining. The cold forming process rearranges the grain structure to follow the parts shape. This characteristic eliminates the potential for porosity fatiques.

Accuracy of critical tolerance

close and critical tolerances can be held repetitive and by high production speed.

Design freedom

A design freedom is provided whereby more intricate contours and shapes can be derived that would require many different and cost prohibitive machining or secondary processes.

Contact us today to learn more about what we can offer